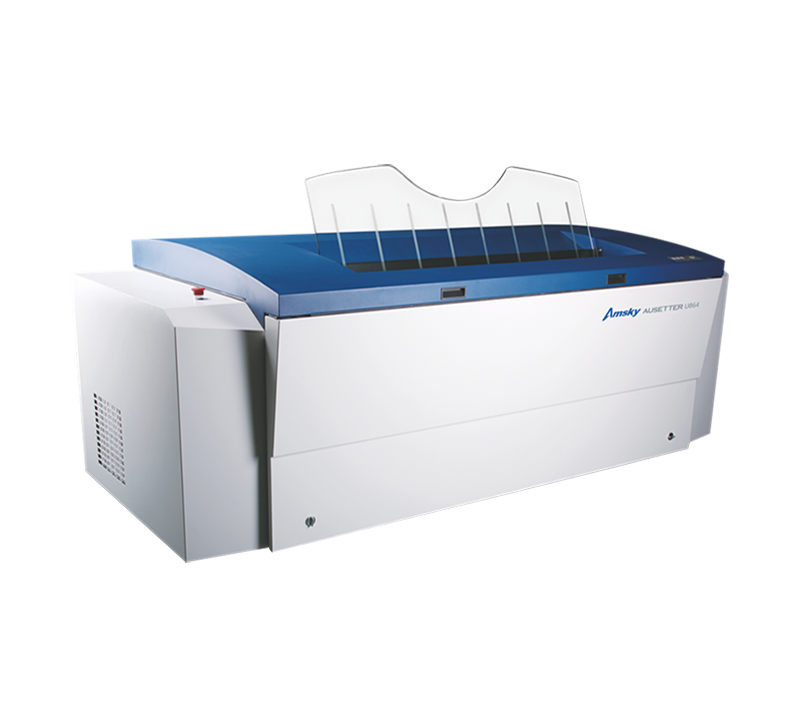

CTP Machine Improve Your Printing Shop Productivity

CTP Machine replaces the traditional exposure method

Using CTP Machine no need to buy the traditional film

One single operator can use CTP Machine to complete all the plate-making work

Min. Plate Size: 300×400mm

Max. Plate Size: 1,163×940 mm

Min. Plate Size: 300×400mm

Max. Plate Size: 1,470×1,180 mm

Min. Plate Size: 300×400mm

Max. Plate Size: 1,680×1,350 mm

Why over 500+ customers use our CTP machine

Over 10+ years of CTP Machine technology accumulation and development make our CTP Machine quality best.

Our CTP Machine equipment with the external drum makes the CTP Plate fit tightly on the drum, and the technology is better and advanced, making you maintain it easily.

CTP Machine replaces the traditional exposure method, which eliminates the occurrence of dirty spots and sun-out in the traditional exposure process so that you can reduce the waste of plates caused by errors in the printing process. And make your image CTP Plate more convenient and faster.

After using CTP Machine you no need to buy the traditional film, no film expenses, so you save production costs.

A single operator can use CTP Machine to complete all the plate-making and plate-washing work by operating the computer, which saving you labor costs.

Our CTP Machine supplies our customers’ two-year warranty, any parts damaged, free replacement for you, so that you can use our CTP Machine with confidence, no quality concerns.

After you buy our CTP Machine, we will provide the installation site instruction manual. Before the CTP Machine arrives at your factory, we will assist you to make the wiring and plumbing layout of the installation site.

In the shipping process, strong wooden box transportation to ensure your CTP Machine safely.

Our CTP Machine Engineers are proficient in English, help customers solve problems in real-time, provide video communication, and remote computer collaboration. And our engineer will train your operator until the operator can operate CTP Machine proficiently

We provide the operation instruction videos, English documents, and common problem checklists, let your operator operate the machine easily and skillfully.

CTP machine is the best CTP plate making machine in your printing shop. Except You can use CTP machine image your own printing business, and you can also use your CTP machine image printing plate for other printing shops with rich profit.

- Technical Specifications

- Manufacturing

- Video

| Model | U832 | U848 | U864 |

| Exposing Method | External Drum | ||

| Imaging system | 32 channels | 48 channels | 64 channels |

| Discrete 405nm laser | |||

| Output speed | 16 plates / hour | 22 plates / hour | 28 plates / hour |

| 1030mm x 800mm, 2,400dpi | |||

| Plate size | Max. 1163 x 940mm; Min. 400 x 300mm | ||

| Plate thickness | 0.15mm~0.3mm | ||

| Resolutions | 2,400 dpi | ||

| Repeatability | 0.01mm | ||

| Interface | USB 2.0 / USB 3.0 | ||

| Plate Loading | Manual | ||

| Net Weight | 900KG | ||

| External dimension | 2,320×1,080x960mm (L x W x H) | ||

| Power supply | Single-phase: 220V; Max Power (Peak value): 4KW | ||

| Environment | Operating temperature range: 15-30℃ | ||

| Recommended temperature: 21-25℃, Humidity: <70% | |||

For manufacturing CTP Machine, our factory has 2 key technologies namely laser technology, precision motion control system, and has been awarded 55 software copyrights, 95 patents for utility models, and 6 patents for invention.

CTP Machine: The Ultimate FAQ Guide

In this guide, you will learn everything you need to know about CTP machine.

From basic definition, advancements in technology, classification, benefits, quality standards and cost among other vital aspects.

So, if you want to be an expert in computer to plate machines, read this.

What is CTP Machine?

Computer to Plate machine refers to a type of equipment used in modern printing through an integrated process.

The process is streamlined in an aspect that takes a finalized file from a computer and outputs it to a plate directly.

This equipment is well known for its ability to help a printer increase performance, productivity and optimize quality on prevailing offset presses.

Plates in CTP machine are fundamental since they come in handy in imaging in a printing process.

CTP machine is vital since the direct plate imaging method allows it to eliminate troublesome film processes.

It comes in different sizes with varying capacities, which is vital since it broadens your choice options.

What are the Benefits of Using CTP Machine?

Investing in a computer to plater machine is quite beneficial.

In the recent past, this equipment has improved modern printing process and the entire industry significantly.

Some of the notable advantages of using a CTP machine include the following;

- CTP machine eliminates the demanding and tedious steps required for conventional plate making.

Typically, you won’t need film workflow and stripping operations, which is fundamental since it saves a lot of time.

- The overall print quality of the final product when using CTP is machine is ultra-high. Ideally, this is often a result of eliminating the dot gain associated with plate imaging from the film.

- This machine enhances easy copy changes since they are made to a digital file imaged onto a plate.

Of course, this is contrary to producing new films and strip them into a flat for burning on the plate.

- There is significant human error reduction when using CTP machines since the need for manual stripping and plate-making is eliminated.

- CTP machine enhances easier, safer, and relatively efficient than storing film and flats. Films and flats can easily be damaged by handling or storage and need a large amount of physical space.

- It is available in different output capacities, which is vital since it allows you to choose one that meets your demands.

In essence, you can obtain a CTP machine based on your budget and other printing needs.

Which Printing Technology Methods can you use with CTP Machines?

There are three main methods of printing technology that you can use with CTP machines. These techniques include the following;

Internal Drum Imagesetters

This technology involves a fixed plate fixed in the CTP machine inside a cylinder.

The imaging head moves along the cylinder axis, thus exposing the plate.

To duplicate the image, a rotating mirror at the end of imaging head interchanges around the axis to beam the laser on plate’s part.

It is a technology, which can increase difficulty of use numerous lasers simultaneously.

Using a single laser also offers its unique benefits, such as exposing light intensity over the whole plate during imaging period.

External Drum Imagesetters

This imaging printing technology features a simple construction type, enabling operators to organize multiple image heads next to one another.

All these several image heads are used at the same time.

In this printing method, plate wraps around a drum rotating around its axis.

While at it, the imaging head moves along an axis, focusing the laser beam onto plate’s surface.

Significantly, this type of production reduces process time needed to expose printing plates.

Flat-bed Imagesetters

In this technology, an image is reproduced line-by-line onto a fixed flat printing plate from a laser beam.

Set-up of the laser beam in flat-bed imagesetters provides less accuracy at the edge of a printing plate.

Therefore, it is more common for printing smaller formats or any type of image where relatively low-quality expectations are acceptable.

What are the Factors to Consider when Buying CTP Machine?

When shopping for an ideal CTP machine, you must be meticulous to ensure you obtain one that meets your demands.

Some of the factors you need to have in mind when looking for this type of machine include the following;

Specifications

Different types of CTP machines feature varied specifications depending on various projections.

It is essential to look into all the suitable specifications you would need to get from this machine.

Essentially, a CTP with all the ideal specifications for your needs enables you to attain the necessary printing efficiency and performance.

Size

Size is an important consideration when buying a CTP machine.

Technically, these machines come in varied sizes, making it possible for you to determine the right one for your needs.

Technically, you need to consider your room space before deciding on the particular CTP machine to buy.

Production Output

Of course, different CTP machines have varied production outputs based on processing time.

When selecting the right one, you must consider the production output, which suits your printing demands.

Flexibility

An ideal CTP machine to consider should be relatively flexible.

Of course, this should be from the types of plates it uses and the ability to print different designs and sizes.

Usability

It is also imperative to ensure you are buying a CTP machine you can easily use.

Some come with additional features, which require in-depth knowledge to operate and successfully execute.

Make sure you understand all the functional aspects of your preferred CTP machine before purchasing it.

Cost

The price for purchasing an ideal CTP machine is a necessary consideration to always factor in when shopping for one.

Always go for one that suits your budget but at the same time offer value for money.

What are the Components of CTP Machine?

A typical CTP machine is made of a wide range of parts and components designed for particular functions.

All these parts are vital since they facilitate efficiency, performance, and quality prints.

However, the major components of CTP machine include the following;

i. Autoloader

This component is programmed by computer prompts to load the materials automatically in the CTP machine.

It resembles a hopper where the printing materials are automatically loaded to the machine for direct imaging and printing.

In some instances, it is referred to as an auto-feeder, and its size varies depending on the actual CTP machine’s size.

ii. Processor

It refers to logic circuitry, which responds to and processes the primary instructions driving the computer to plate machine.

Processor, in this case, is regarded as most necessary integrated circuitry in the machine.

The role of this component is to interpret most of the commands issued to the CTP machine during printing process.

iii. Control Unit

A control unit in a CTP machine consists of numerous parts, including an electrical cabinet, numerous electrical components, and control systems.

All the elements within the control unit regulate numerous systems and parameters of this equipment.

It features buttons, which relay signals for a specific command upon pressing, thus allowing it to operate seamlessly.

iv. Stacker

Stacker is the component in a CTP machine that collects printed materials upon completion of the process.

It is located at the furthest end of the machine, always open to allow faster cooling and easy collection of finished prints.

v. Haul-off Unit

It is a device in a CTP machine, which pulls the printed material to move forward.

Haul-off unit is a vital component since it determines the speed hence determining the overall production output.

vi. Driving Motor

This refers to a component, which converts electric power to provide energy to run the CTP machine.

The essence of a driving motor is to generate sufficient energy to allow the machine to run accordingly.

Often, the motor’s size tends to vary depending on the actual size of the computer to plate machine you are using.

How does CTP Machine Work?

The working principle of a CTP machine work is quite technical.

Simply put, though, this equipment has a thermal material, which becomes the image area and transferred to the plate.

The machine is integrated with various technologies such as a wetting agent that keeps non-image area clean during a print run.

CTP machine can produce a short run of 50000 impressions immediately after imaging.

In case a longer run is required, thermal material must be bake onto the cylinder.

After the printing is complete, the thermal image material is automatically cleaned from the plate cylinder.

This allows the cylinder to be ready for reimaging of the next task.

What does CTP Workflow Entail?

CTP workflow entails numerous elements such as preflight, imposition, RIP, plate imagesetter, and processor among others.

A typical CTP technology, there is an assumption of a print shop, which receives digitally printing data from outside.

It first checks it for completeness, accuracy, and printability in what is referred to as preflight check.

The imposition is then carried out, and the file is sent to a raster image processor (RIP).

Proffer then checks, agrees, and returns the file to expose the command issued.

Plate is kept in the platesetter is punched and exposed with laser light to immediately expose plate processed in Automatic Plate Processor.

What is the Recommended Output Capacity of a CTP Machine?

Figure 4 A2 Size Printing Machine

Different types of CTP machines have varying production capacities depending on various prevailing elements.

For instance, output capacity is often based on a particular model of the machine.

The specific technology computer to plate machine uses also determines its actual output capacity.

Another element, which determines the precise output capacity of a CTP machine is the plate sizes.

What Materials are used to Manufacture CTP Machines?

Different brands of CTP machines are manufactured using various materials.

Technically, different components of this machine are designed using different materials based on the specific function.

However, some of the popular materials include the following;

- Carbon steel

- Stainless steel

- Cast iron

- Polycarbonate

What are the Main Types of CTP Plates available?

There are three main types of plates commonly used in CTP machines, and they include the following;

a) Thermal CTP Plates

It refers to a design with relatively low sensitivity to natural light.

Often, the infrared laser is utilized for exposure and can be operated in somewhat bright room conditions.

Generally, thermal CTP plates have better reproducibility, sharp edge, and high resolution.

Moreover, it has excellent printability and a printing resistance of about one million times after baking.

As such, this type of CTP machine plate tends to dominate commercial printing.

Even so, it has relatively high requirements for humidity and ambient temperature.

Also, it has a relatively inferior sensibility compared to other types of CTP plates.

Figure 5 CTP Plate

b) Silverhalogen Plates

Figure 6 CTP Plate

One major benefit of this design of CTP machine plate is its high photo-sensibility.

It is arguably the type of CTP plate with the fastest photo-sensitive speed.

Nevertheless, one of its shortcomings is that it is quite expensive, obvious with photo-sensitive materials.

Secondly, it has high requirements for inks and a relatively poor printing resistance.

Development process of Silverhalogen plates can also trigger toxic waste liquid hence polluting the surrounding.

c) Photopolymer Plates

This design of CTP machine plate consists of an aluminum plate base, a surface layer, and a photo-sensitive layer.

Such plates are quite active and require low energy to perfectly expose the image.

Therefore, it is widely used in newspaper and magazine industry.

However, it has a somewhat poor dot recovery compared to thermal CTP plates.

Figure 7 CTP Plate

How durable is CTP Machine?

The durability of CTP machine is contingent on a wide range of factors.

For instance, the type of materials used for constructing its different components.

Most of these equipment are designed using hardy materials such as cast iron, stainless steel, carbon steel, etc.

However, the specific grade of such materials is what determines the overall durability of the CTP machine.

Ideally, a CTP machine manufactured using high-grade materials will last longer than one made using low-quality materials.

Another element, which determines durability of this machine is care and maintenance.

Ordinarily, a CTP well maintained and taken care of will last longer than a poorly maintained one.

Therefore, you need to ensure you maintain and take care of this equipment properly according to the stipulated schedule.

And most importantly, the intensity of printing the CTP machine is subjected to also determine its accrual durability.

One exposed to high intense printing will experience faster wear and tear hence leading to a shorter life-span.

The bottom line is CTP machines are generally hardy and durable. However, the actual life-span is dependent on a host of factors like the ones described above.

What are the Specifications of a Suitable CTP Machine?

Figure 8 CTP Machine specifications

CTP machines come in various models from a wide range of brands.

Different generations of these machines also have varying specifications from one brand to another.

Therefore, most of them are bound to have different auxiliary features depending on a particular manufacturer or your demands.

However, specifications for a suitable CTP machine is largely dependent on your particular demands.

The base features, which an ideal CTP machine needs to have, include but not limited to the following;

- Digital speed processing

- Ideal speed adjustment

- Adjustable temperature, time, and submerged development

- Microprocessor control system

- Temperature control system

- Glue automatic circulation system

- Automatic cleaning and gluing roller

- Unique plate loading plate separation technology

- Multi-axis motion axis control system

- Perfect drum structure

What is the Cost of the CTP Machine?

The price of CTP machine is dependent on different variables.

One is the actual brand you are purchasing. There are numerous brands in the market ranging from high-end to less-known in the market.

High-end brands tend to be more expensive since they have established a reputation and cement their market space.

Another CTP machine cost determinant is the specifications.

Most of the time, different models from different brands have various properties depending on the application and end-user needs.

The more the auxiliary specification, the costlier the machine and vice versa.

Also, the material used for manufacturing the CTP machine influences the overall price of the same.

Essentially, premium quality material CTP machines are relatively expensive than ones manufactured using ordinary grade materials.

The size of this equipment is another determinant factor of the exact cost. Size determines several elements such as output capacity, performance, and speed among others.

Therefore, bigger CTP machines tend to be more expensive than smaller units.

In a nutshell, the price of CTP machine is not fixed. It is dependent on a wide range of factors, as mentioned above.

What are the Types of CTP Machine Systems?

CTP machine uses two major types of technologies, and they include the following;

1) Visible Light Systems

Visible light systems are closely related to film-based systems.

As such, most of the visible light systems in CTP machines still depend on silver halide coatings on the plate instead of film.

Visible light systems still require fixing or pre-heat and washing steps, which produce silver-bearing wastes.

Plates in this system are developed and finished similar to the process of traditional film process.

Nevertheless, CTP machines, which use this system must be operated in an environment where ambient light is tightly regulated.

Essentially, exposure to unwanted light tends to ruin the plate.

This makes CTP machine light-based systems have difficulty in producing relatively consistent plate quality.

2) Thermal Systems

It is the second type of CTP machine systems.

As the name suggests, this system uses heat to image the plate.

Immediate the ideal temperature threshold is attained, the plate is transformed in that spot.

Plates in these systems are not overexposed, but they still need developing and finishing similar to traditional film process.

Moreover, CTP machines, which use this technology, do not need ambient light in a controlled environment.

This system can as well do finer detail sharply and can accommodate line screens greater than 200.

However, CTP machines using this system tend to be a bit expensive compared to other systems.

Also, they require comparatively more frequent maintenance and replacement.

Nonetheless, other types of CTP machines systems include;

- Process free

- Chemistry free

- Direct imaging systems

The efficiency of these systems on particular CTP machines vary based on a wide range of factors and settings.

How do you Select the Best CTP Machine Manufacturer in China?

When shopping for an ideal CTP machine, one of the most important elements to look into is the manufacturer.

Largely, it enables you to determine the right model, which suits your specific requirements.

However, in finding the best one, you need to look into several guiding factors.

Some of these elements you should always have in mind include the following;

Quality of the Machine

You must never overlook quality the manufacturer produces irrespective of your budget.

Always ensure you buy this equipment from a reputable manufacturer producing high-quality components.

Affordability

Generally, CTP machines tend to be relatively expensive, of course, depending on the particular specifications you’re choosing.

However, it is always important to get a manufacturer that can offer discounts, especially when buying multiple units.

In essence, it helps you to save a considerable amount of money, which you can divert to other logistic needs.

Excellent Customer Service

Buying and operating these machines are different elements.

At times, the machine may develop issues hence the need to get guidance from the manufacturer.

The only suitable way of attaining this is by dealing with a company that can answer your queries and handles all your concerns aptly.

Auxiliary Services

It would also be essential to consider purchasing a CTP machine from a manufacturer offering additional after-sale services.

For instance, packaging, warehousing (if need be), and shipping are some of the auxiliary services an ideal manufacturer should provide.

Warranty

Since CTP machines are quite pricey, it would be vital to consider a manufacturer offering a reasonable warranty.

In principle, this shows the dealer is reliable and confident in the machine.

Does CTP Machine have Warranty?

Yes.

Most reputable CTP machine manufacturers offer a valid warranty.

Of course, the warranty period, terms, and conditions vary from one manufacturer to another.

It is the reason you need to inquire about all the fine details regarding the warranty before you close the deal.

What is the Suitable Way of Shipping CTP Machine from China?

There are two major ways you can use to ship CTP machines if you are importing to an overseas country from China.

Airfreight is seemingly, an ideal method if you need to get the consignment within a relatively short time.

It is a safe and more convenient option. However, airfreight is relatively costly, especially if the machine is a bit big.

Another option you may explore is ocean freight. Arguably, it is the best method to choose for shipping different types of CTP machines.

Ocean freight is relatively affordable, especially if you are shipping large or numerous CTP machines.

Even so, it is relatively slow and can take between 30-60 days, depending on your location.

Are there any Shortcomings of CTP Machine?

Yes.

The initial cost of purchasing and shipping the machine can be quite expensive, depending on the particular brand.

Also, the running cost can be high depending on the intensity and frequency of work you carry out.

What are the Quality Standards Certifications for CTP Machine?

Some of the main quality standards and certifications for CTP Machine are:

ISO9001

This refers to a set of international quality management systems and guidelines.

It describes manufacturer’s ability to conform to the required processes, quality, safety, and efficiency of products, services, and systems.

CE

CE certification refers to an administrative marking, which indicates this machine’s conformity to health, safety, and environmental protection.

Essentially, all the aspects of CE certification conformity are set according to the European Community standards.

Why should you Consider Buying CTP Machine from China?

Figure 9 CTP Plate making process

There are several reasons why you need to buy a CTP machine from China, including the following;

Affordability – In China, you are likely to get affordable CTP machines since several manufacturers offer great discounts.

Variety – You can also get a wide range of brands, models, or sizes of CTP machines in China. The essence here is to allow you to obtain the particular one, which suits your needs.

Quality – China is a marketplace that guarantees you high-quality computer to plate machines for your needs.

Ideally, you can always get the right quality you want, which of course, gives you value for money.

Easy shipping – You can always choose the best shipping methods you prefer when importing this machine from China.

The carriers are several hence enabling you to find a better deal at cost-effective rates.

At Easypress, we design and manufacture a range of CTP machines depending on your specific needs and requirements.

Of course, this is alongside other printing machines such as plate backing machine, Flexo CTP, plate punch machine and plate exposure machine, amongst others.

Contact us now for all your CTP machine needs.